SPROCKET Attributes

PLATE CENTER SPROCKETS

Sprockets are furnished in two basic kinds . . . Plate center and Spoked Arm. Plate centers are commonly used on smaller sprockets whose size prohibits the usage of spoked arms and on drives and conveyors which are subjected to frequent shock loads. These are also used once the highest allowable chain pull is greater than that which Spoked Arm Sprockets

can withstand.

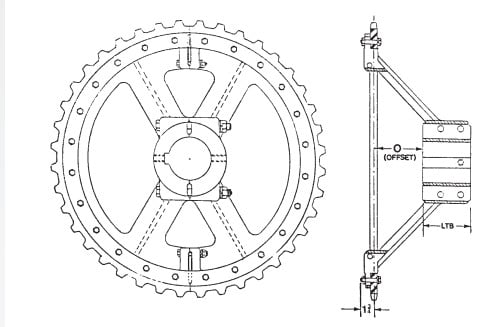

SPOKED ARM SPROCKETS

Spoked arms are observed on big diameter sprockets. They may be utilised to cut back weight and facilitate dealing with.Lightening holes can also be utilized to cut back excess weight.

CHILLED RIM DISHED AND

FABRICATED DISHED

When making cast prockets, we use a distinctive chemistry of gray iron that enhances the capacity of the in the iron to form a difficult “chilled” layer to the rim from the sprocket. All sprockets really are a common class thirty gray iron. This applies to all regions of the sprocket which can be not chilled this kind of since the hub and net parts. Surfaces have a minimal brinell hardness of 400 in excess of the complete tooth professional?le.

Fabricated dished sprockets are produced to order. Products and hard-ness are custom-made for your prerequisites.

CHAIN SAVER SPROCKETS

Chain Saver sprockets  give added life to chain for the reason that on the exclusive ?ange development to the rim. The chain side bars rest to the ?ange as chain wraps about the sprocket, retaining the chain about the true pitch line and distributing put on more than a higher speak to spot.

give added life to chain for the reason that on the exclusive ?ange development to the rim. The chain side bars rest to the ?ange as chain wraps about the sprocket, retaining the chain about the true pitch line and distributing put on more than a higher speak to spot.

HUNTING TOOTH SPROCKETS

Hunting Tooth Sprockets final longer than ordinary sprockets and operate on this principle: Hunting Tooth Sprockets have an odd number of teeth and are half the pitch from the chain. So, each time the sprocket helps make a revolution, the chain links engage a fresh set of teeth, forward with the previously engaged set. Just about every tooth can make make contact with together with the chain only half as numerous times since it would on the reg-ular sprocket, therefore doubling the daily life of the sprocket.

SEGMENTAL RIM SPROCKETS

Segmental Rim Sprockets are intended to get rid of pricey shut down time during set up and adjustment. They include a re-movable segmented rim plus a solid or split entire body which are bolted collectively. To obtain extra wear from this kind sprocket, soon after con-siderable use, the rim sections may perhaps be simply reversed, so that the chain makes speak to with all the opposite sides of the teeth. Bodies or entire sprockets may well be replaced without the need of removing shaft or bear-ings, producing this type of sprocket pretty desirable economically be-cause with the cost savings in labor and shut-down time.

Broad FLANGE SPROCKETS

These Sprockets are utilized in a lot of industries this kind of since the lumber and paper industries as sprockets for the delivery finish of conveyors. The broad ?ange or side extension acts being a guard and aids retain materials from being wasted since it comes off the end from the conveyor.

TRACTION WHEELS

Traction wheels can be found within a wide array of sizes and forms to ?t most chains. They are really furnished in a plate-center type with op-tional lightening holes if demanded. Traction wheels might be both solid, split or segmented construction.